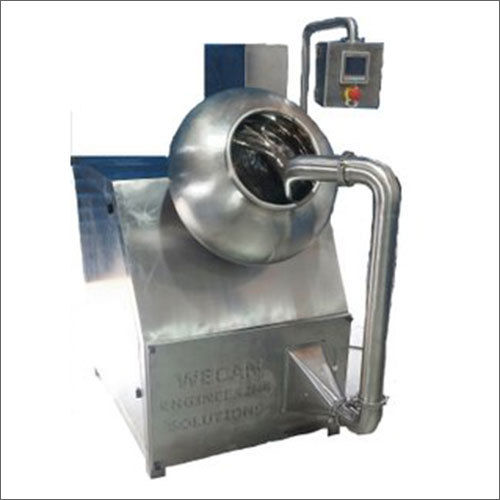

Stainless Steel Small Chocolate Coating Machine

Price 55000 INR/ Set

Stainless Steel Small Chocolate Coating Machine Specification

- General Use

- Chocoate Coating

- Weight (kg)

- 75 Kilograms (kg)

- Coating Speed

- Variable RPM

- Heating System

- Electric

- Drive Type

- Electric

- Voltage

- 220 Volt (v)

- Humidification System

- No

- Dimension (L*W*H)

- 30X40X50 Inch (in)

- Color

- Silver

- Warranty

- 1 Year

Stainless Steel Small Chocolate Coating Machine Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- India

- Supply Ability

- 10 Sets Per Week

- Delivery Time

- 10 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Stainless Steel Small Chocolate Coating Machine

Models With Pan Speed Controller and Hot Air Blower.

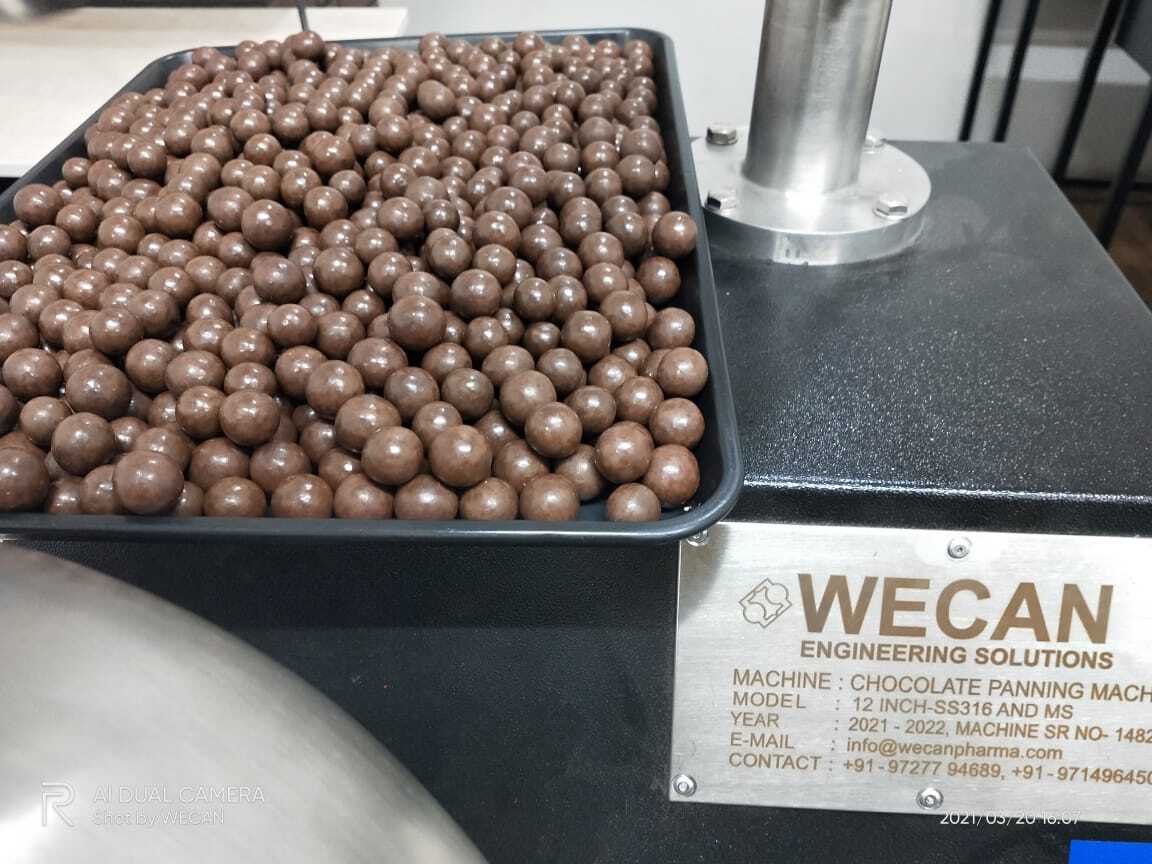

Pan Material Stainless Steel Grade SS316 (100 % Food Grade).

Stand Material Stainless Steel Grade SS304.

Pan Motor Speed Controller with Variable Frequency Drive Included.

Pan Motor On/Off/Reverse/Forward/Main Switch Included.

Design Direct drive.

Hot Air Blower With Auto Cut-off Included.

Digital RPM Meter and Digital Temperature Controller Included.

Precision Chocolate Coating for Every Batch

Experience reliable chocolate coating performance with our stainless steel chocolate coating machine. Its variable RPM settings let you manage coating thickness and consistency effortlessly, ensuring every batch meets your quality expectations. Designed for operators prioritizing precision and product integrity.

User-Centric Design and Durability

Crafted with high-quality stainless steel and a straightforward electric system, this machine proves both durable and easy to use. Its robust frame, manageable size, and hassle-free cleaning process make it suitable for any chocolate production setting, big or small.

Flexible Commercial Delivery Solutions

As an established exporter, importer, manufacturer, and supplier based in India, we ensure prompt and safe delivery of the machine wherever its needed. Our global supply chain enables businesses to access advanced chocolate coating technology efficiently.

FAQs of Stainless Steel Small Chocolate Coating Machine:

Q: How do I operate the stainless steel small chocolate coating machine?

A: To operate the machine, plug it into a 220V power source, set your desired coating speed with the variable RPM control, and use the electric heating system to reach the optimal temperature. Place your products inside, start the machine, and monitor until coating is complete.Q: What types of products can be coated using this machine?

A: This machine is primarily designed for chocolate coating and is suitable for a variety of confectionery items such as nuts, dried fruits, and candies. Its adjustable speed ensures it can handle different sizes and consistencies of products effectively.Q: When is the best time to use this chocolate coating machine in production?

A: The machine can be utilized at any stage where chocolate coating is required, typically after the main ingredient has been prepared and cooled. Its efficiency makes it ideal for continuous or batch production cycles in commercial settings.Q: Where can this machine be installed for optimal use?

A: Due to its compact dimensions (30x40x50 inches) and manageable weight (75 kg), the machine can be conveniently placed in small production facilities, commercial kitchens, or dedicated coating rooms, provided there is access to a 220V electric supply.Q: What is the process for cleaning and maintaining the machine?

A: The stainless steel construction allows easy cleaningsimply wipe down with a damp cloth after use. There are no humidification components, so basic routine maintenance and periodic inspection of moving parts and the electric system are sufficient for longevity.Q: How does the electric heating system benefit the coating process?

A: The built-in electric heating system enables precise temperature control, ensuring smooth and even chocolate flow. This helps achieve consistent, glossy coatings and minimizes product wastage due to overheating or underheating.Q: What warranty and after-sales support are provided with the machine?

A: The machine comes with a 1-year warranty covering manufacturing defects. As an exporter, importer, manufacturer, and supplier based in India, we also provide comprehensive after-sales service, including technical support and spare parts provision.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Coating Pan Category

Tablet Coating Machine

Price 45000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Drive Type : Mechanical

General Use : Tablet Coating

Control System : PLC Control

Voltage : 415 Volt (v)

Stainless Steel Small Chocolate Panning Machine

Price 55000 INR / Set

Minimum Order Quantity : 1 Set

Drive Type : Electric

General Use : Chocolate Panning

Voltage : 220 Volt (v)

Chocolate Panning Machine

Price 45000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Drive Type : Electric

General Use : Chocolate Coating

Control System : PLC Control

Voltage : 415 Volt (v)

Revolving Coating Pan

Price 45000 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Electric

General Use : Industrial

Control System : PLC Control

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS