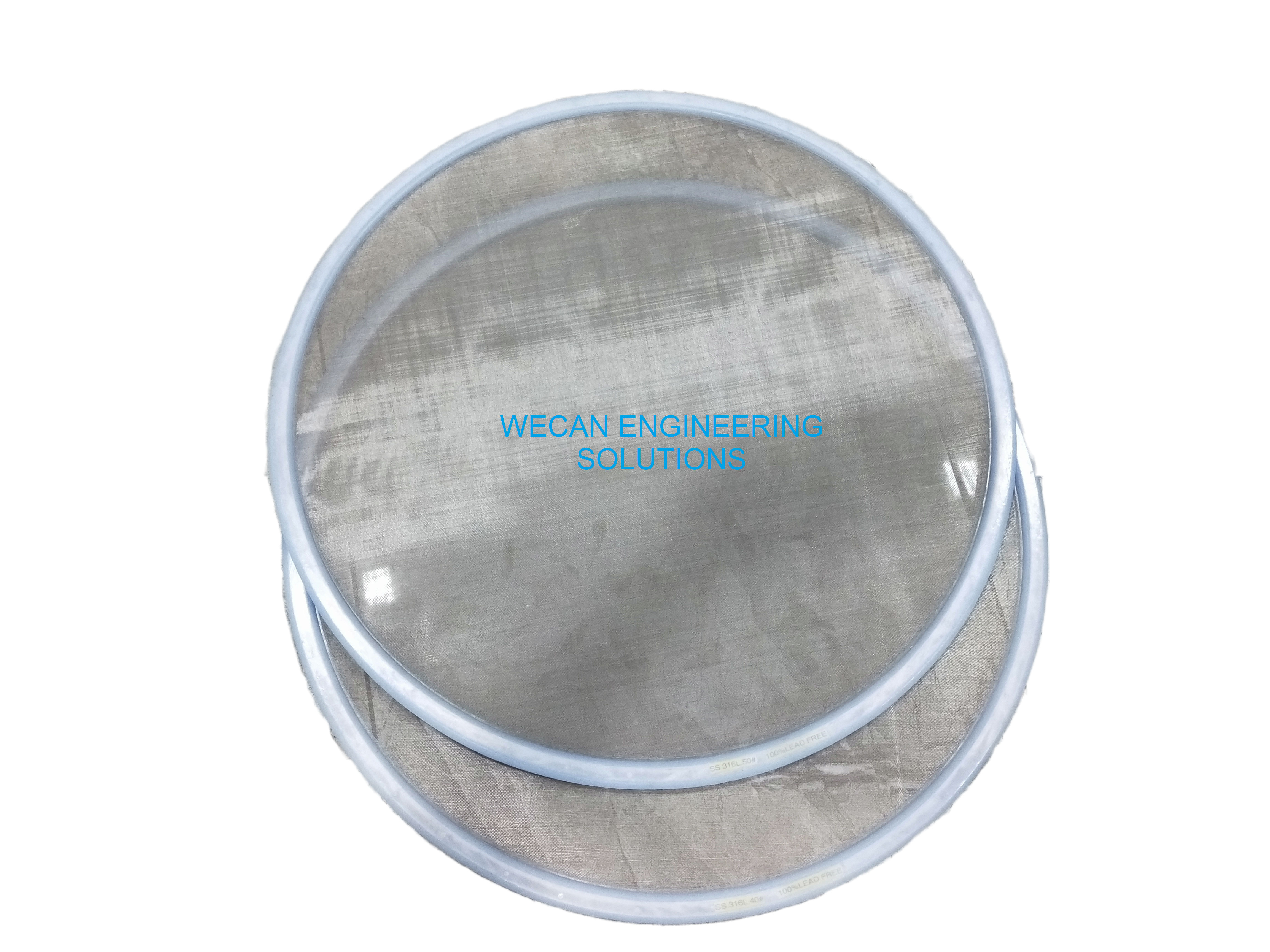

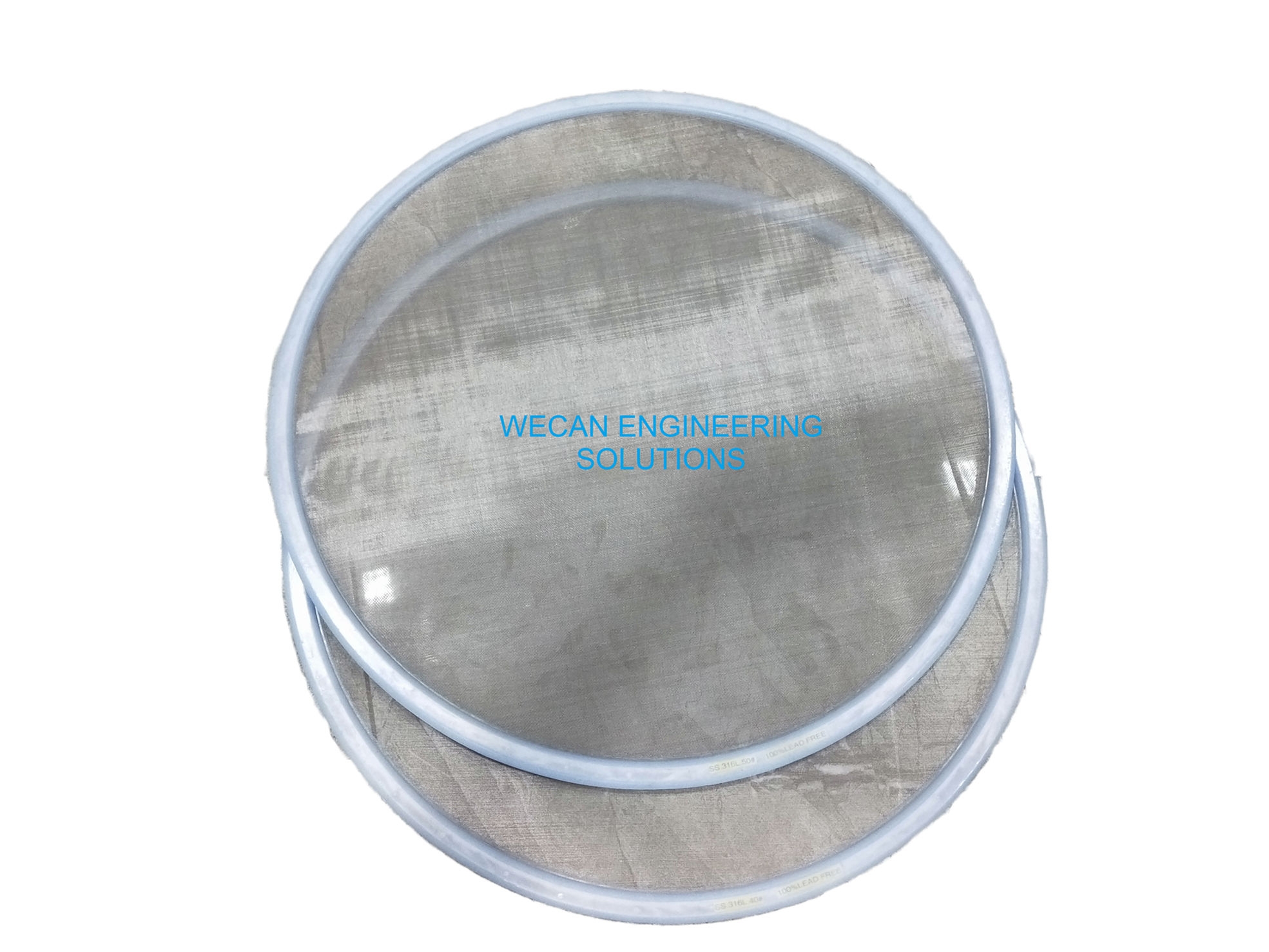

Sifter Sieve

Price 2300 INR/ Piece

Sifter Sieve Specification

- Usage & Applications

- Industriual

- Surface Finish

- Matt

- Product Type

- Machine Parts

- Material

- Silicon And SS316

- Power

- 415 Volt (v)

- Voltage

- 415 Volt (v)

- Surface Treatment

- Painted

- Dimension (L*W*H)

- 36 X 36 Inch (in)

- Weight

- 1 Kilograms (kg)

- Color

- Silicon

Sifter Sieve Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Sifter Sieve

Sifter Sieves of Wecan Engineering Solutions

SIFTER SIEVES TYPES

We offer many types of sifter sieves. Here are some of them:

Vibro Sieves

Multimill Sieves

Linear Vibratory Sieves

Circular Vibratory Sieves

Stainless Steel Sieves

Ensuring Product Quality and Consistency WITH OUR SIFTER SIEVES

Sifter sieves play a crucial role in various industries. Consequently, they ensure precise particle separation for numerous applications, maintaining product quality and removing impurities. Additionally, they enhance overall efficiency.

Key Features:

-

-

Achieve accurate particle separation, ensuring uniform product quality. Additionally, they are constructed from robust materials like stainless steel.

-

Adapt to a range of materials and sizes. Furthermore, they are designed for simple cleaning and minimal downtime.

-

Applications:

-

-

Separate fine powders in pharmaceuticals to meet industry standards. Additionally, they sift ingredients in food processing to ensure product consistency and purity.

-

Grade and separate compounds in the chemical industry for precise formulations. Furthermore, they sieve powders in cosmetics for a smooth texture.

-

Sort seeds and grains in agriculture to improve product quality. Finally, they sift sand and other materials in construction for uniform particle size.

-

Advantages:

-

-

Deliver consistent, high-quality output. Moreover, they facilitate rapid material separation, reducing processing time.

-

Offer low maintenance and operational costs. Additionally, they suit both small-scale and large-scale operations.

-

Silicon Coated Sifter Sieves:

-

-

Provide additional protection against wear and tear. Additionally, they prevent materials from sticking, ensuring smooth operation.

-

Perform well in harsh environments. Consequently, they maintain consistent performance, reducing downtime for maintenance.

-

SIEVES MANUFACTURER IN INDIA

Wecan Engineering Solutions,based in Kheda, Gujarat, is a prominent sifter sieve manufacturer in India. We specialize in producing high-quality sieves, catering to various industries such as pharmaceuticals, food processing, and chemicals. Further more, our sieves ensure precise particle separation, maintaining product quality and consistency. Additionally,Wecan Engineering Solutions offers a range of products, including:

-

-

Standard Sieves: For general sieving applications.

-

Silicon Coated Sieves: Providing enhanced durability and non-stick properties.

-

Stainless Steel Sieves: Ideal for hygienic applications.

-

Wecan Engineering Solutions, a leading sifter sieve manufacturer in India, delivers reliable solutions to meet the diverse needs of our clients.

SIEVEs PRICE

Affordable Sifter Sieves from Wecan Engineering Solutions.

At Wecan Engineering Solutions, we prioritize both quality and cost-efficiency. Therefore, our range of sieves caters to various industries, including pharmaceuticals, food processing, and chemicals, all at competitive prices. Sifter sieve price may be as under.

-

-

Standard Sieves: 1500/- to 3000/- per piece

-

Silicon Coated Sieves: 1900/- to 6500/- per piece

-

Stainless Steel SS316 Sieves: 2300/- to 9000/- per piece

-

We commit to delivering high-quality sifter sieves that meet your budget without compromising on performance. Moreover, for detailed sifter sieve price and customization options, please contact Wecan Engineering Solutions directly.

SIFTER SIEVEs SIZE

Sifter Sieve Sizes by Wecan Engineering Solutions

Wecan Engineering Solutions offers a variety of sifter sieves in different sizes to meet diverse industry needs. Additionally, our sieves come in various diameters and mesh sizes, ensuring precise particle separation for your specific application.

-

-

Diameter Options: Available in diameters ranging from 300 mm to 1500 mm.

-

Mesh Sizes: Up to 500 mesh for fine particle separation.

-

Customization: We offer customized sizes and mesh configurations to meet your unique requirements.

-

Further more, our sifter sieves deliver high performance and efficiency, ensuring consistent product quality. Lastly, for detailed information on sifter sieve size and customization options, please contact Wecan Engineering Solutions directly.

Efficient Material Separation

Specifically engineered for industrial usage, the Sifter Sieve ensures highly efficient separation of powders, granules, and other materials. Its combination of silicon and SS316 provides excellent resistance to corrosion and wear, making it suitable for continuous operations in demanding environments.

Superior Build and Durability

The sieve features a matte silicon finish and painted surface treatment, increasing longevity and minimizing maintenance needs. With its sturdy construction and quality materials, this product withstands frequent heavy-duty use, providing consistent performance over its lifecycle.

Flexible Industrial Applications

Adaptable for various industries such as pharmaceuticals, chemicals, food processing, and minerals, the Sifter Sieves large dimensions (36 x 36 inches) and 415 Volt operational capacity make it suitable for both small and large scale sieving processes.

FAQs of Sifter Sieve:

Q: How is the Sifter Sieve used in industrial applications?

A: The Sifter Sieve is employed for segregating, filtering, and grading materials such as powders, granules, and solids in industrial processes. Its robust construction allows it to operate smoothly under continuous, high-volume production environments.Q: What materials are used in constructing the Sifter Sieve?

A: This sieve is made from silicon and SS316 stainless steel, combining the flexibility and chemical resistance of silicon with the strength and corrosion-proof properties of SS316 for optimal durability.Q: Where can the Sifter Sieve be installed?

A: It can be integrated into a wide range of industrial setups, including manufacturing plants, food processing units, and pharmaceutical facilities, thanks to its large 36 x 36 inch dimension and compatibility with standard 415 Volt power supplies.Q: What is the surface treatment process for the Sifter Sieve?

A: The Sifter Sieve undergoes a painted surface treatment along with a matte silicon finish, which enhances its resistance to wear, moisture, and chemical exposure, prolonging its operational lifespan.Q: When should the Sifter Sieve be used in the production process?

A: It is best utilized during initial material processing stages or quality assurance checks, where consistent particle size and purity are crucial for downstream processes and final product quality.Q: What benefits does the Sifter Sieve offer to industrial users?

A: Users gain reliable separation efficiency, minimal maintenance requirements, and enhanced operational safety due to the sturdy and corrosion-resistant materials. This increases overall productivity while reducing downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS